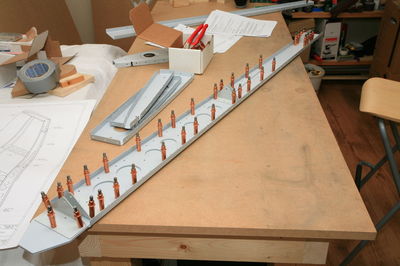

After a busy week I got back into the workshop today. Bought a couple of door hinges for 30 cent a piece, including the screws. Not too bad. I also found 1/8" dowels in a model shop. Equipped like this I built a bending brake from 2x4s which I still had at home, taped the dowels in the back of the rudder to prevent it from being crushed, and started bending.

The other builders are right. Boy, this takes quite some force! It didn't take long until I attached two large clamps to the brake:

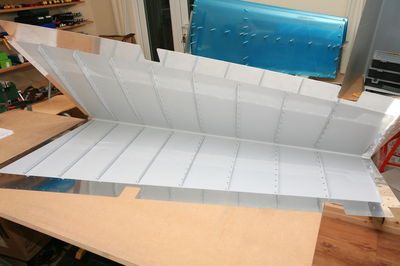

When I built the brake I had left a 1/8" gap between the lumber, but now I think that's too wide. It was hard to get the last bit bent, even though I took out the dowels. Nevertheless, in the end it worked out fine. Looks already like a rudder:

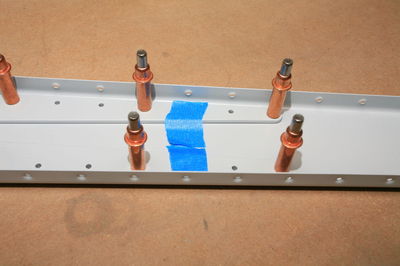

Closeup of the trailing edge. Good enough for government work: