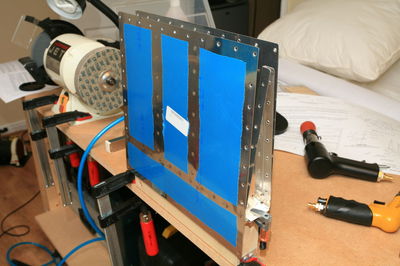

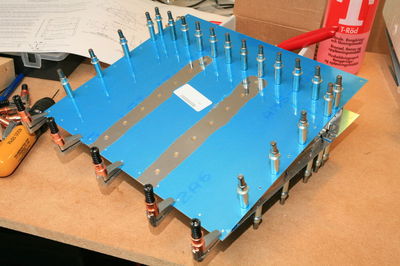

Two days ago I made some more progress on the aileron training kit. First I made a thin dimple die from a piece of steel and dimpled the four missing holes in the ribs. Then I made a simple jig to clamp everything to the workbench and riveted the skins to the spar. Boy, I'm glad that this is a training kit. I think I drilled out about 1/3 of the rivets out -- some because they were bad, some because they were so-so and I wanted to practice a little more. I also scratched the spar a bit when I slipped with the bucking bar, and the skin when I slipped with the center punch (don't ask).

Squeezing the rivets in the ribs was a breeze, except of course for the rivets closest to the trailing edge (which had to be bucked).

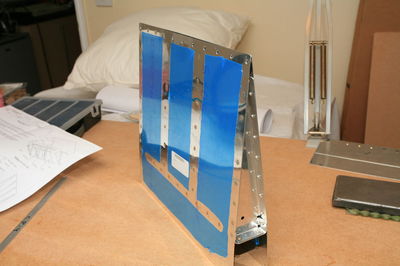

Today I countersunk the wedge for the trailing edge (not deep enough, but hey -- it's a training kit). Riveting the trailing edge was much easier than I thought, and it came out nice and straight:

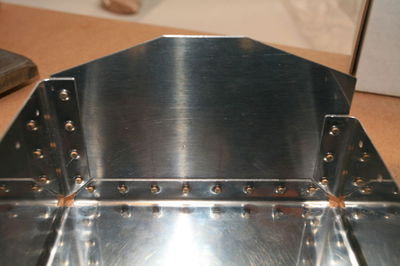

Also rolling the leading edge went very smooth:

So now I have my first aileron! Well, sort of at least. It was a good idea to start with the training kits. I definitely learned a lot and feel confident to start with the real parts now.