Today was a good day. I started working on the rudder skeleton. First I trimmed the R-710 rudder horn brace. I didn't take a "before" picture, but here is the brace after trimming:

When you do this, be careful not to trim to much. It's very easy to run into edge distance problems at the skin hole nearest to the spar (the blue Sharpie mark on the far right bottom).

I had rounded the top edge of the R-405PD rudder horn already yesterday, to fit it to the R-704 rib. So I could cleco the rudder horn and the rudder horn brace to the rib:

Looks good, everything seems to fit.

Next step was match-drilling the R-717 spacer to the spar. I marked the center line, drilled the middle hole and clecoed the spacer to the spar such that I could see the center line in the two other holes. Like this I knew that it is straight.

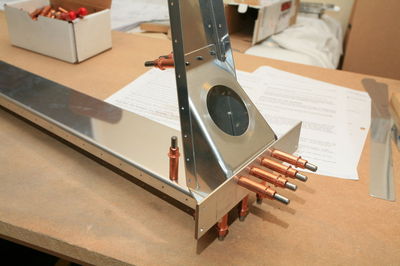

Having the spacer, I then could cleco the whole assembly to the spar. As you can see, I also clecoed the reinforcement plates on. Oh, and all the parts are already edge finished except for the rudder horn.

After some thinking I'm pretty sure now that I can use solid rivets in all holes in this area. We'll see. I drilled all the holes in the spar web and the holes that hold the rudder and rudder brace together and to the bottom rib to final size. Then I prepared the tip rib (edge finishing, fluting) and drilled it to the spar, too:

As finale I deburred and scuffed the skin of the vertical stabilizer, and dimpled the holes I can reach with the squeezer. I didn't want to use the C-frame dimpler late in the evening, for obvious reasons. No photos, sorry.